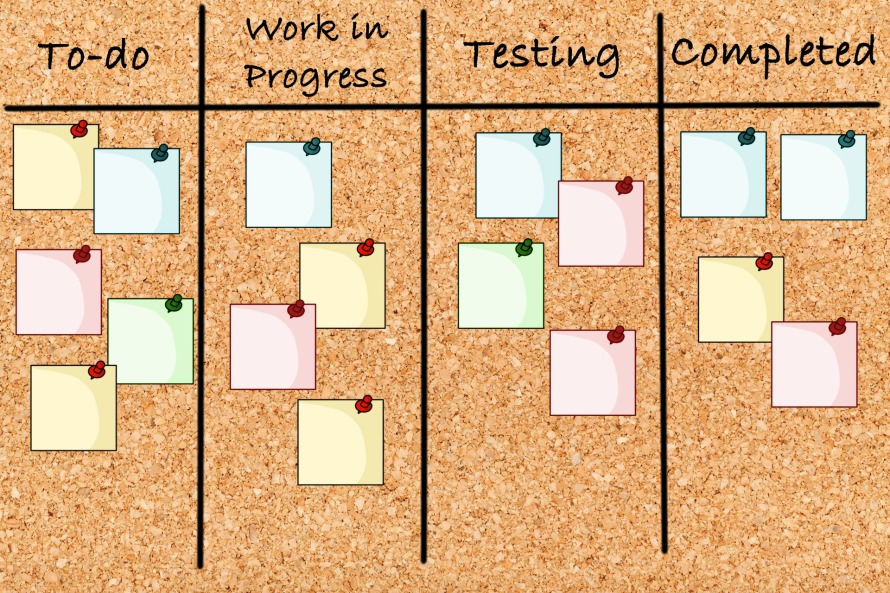

Kanban in Agile is more than just the kanban boards, and the kanban boards are not even required. Within Agile, Kanban stresses a need for a visual workplace. Kanban boards were created to satisfy that requirement.

Kanban in Agile is more than just the kanban boards, and the kanban boards are not even required. Within Agile, Kanban stresses a need for a visual workplace. Kanban boards were created to satisfy that requirement.

If you would prefer to learn about Kanban in a quicker video overview, please check out the 3-minute explainer Video: What is Kanban? or check it out below. Otherwise, keep reading to learn about Kanban.

*Check out the free Kanban CFD template for Excel

The Origins of Lean kanban

Lean Kanban started with Taiichi Ohno. In the 1940s and 1950s, he was a production engineer at Toyota. He was tasked with making Toyota as efficient as Detroit automakers (Toyota).

Taiichi Ohno came to the United States during that time and noticed something different about how Americans shopped for groceries compared to how the Japanese did it at the time. Customers only took the items they needed, and stores only provided a limited supply on the shelves (IBQMI).

Taiichi Ohno began to view manufacturing processes as a store (IBQMI). The preceding process being the supplier for the process next in line. If one process was not ready to consume the efforts of the prior process, then the prior process must stop producing.

“Something amazing begins to happen when you have an idea, define that idea, and give it a name. You begin to think about it as an entity and it can help change your perspective.” – AUTONOMATION AND THE HELPER ROBOTS

The rate of demand controls the rate of production (IBQMI). This creates the pull system effect. You pull the items through the process flow. If the last process needs input from the prior process, it pulls in that input creating a chain reaction down the line that keeps processes producing.

This is different than a system that tries to push the outputs through the process flow. Those processes will keep producing as long as they have the required inputs to the process. Imagine a grocery store loading up all their inventory on the shelves and producers of food items sending their goods whether the store needs them or not.

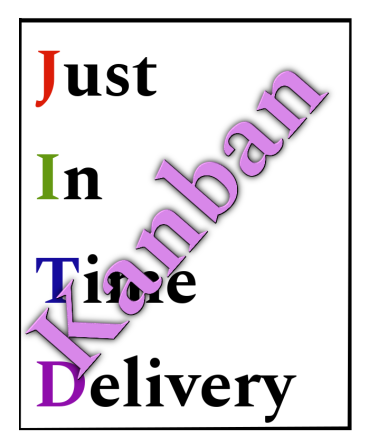

This idea of Taiichi Ohno’s became known as Just In Time (JIT) manufacturing. It formed part of the Toyota Production System and later became part of Lean Manufacturing. Lean kanban became part of JIT manufacturing as a way to organize the workflow in a visual way.

Agile Kanban and Lean Kanban

Taiichi Ohno’s idea for Just In Time (JIT) manufacturing, described in the above section, pretty much describes Kanban in Agile. Kanban in Agile is more or less JIT manufacturing. Although In Agile Kanban, just in time manufacturing is known as Just in Time Delivery.

Confused? Let me phrase it another way.

Kanban in Agile is a method for managing knowledge work that includes JIT delivery practices such as limiting Work In Progress (WIP) and using a visual system, such as a kanban board, to display the current state of the work. It also has some accompanying practices to help enhance or improve the flow of work through the system.

Kanban in Lean is just the visual signaling cards you might put on a Kanban board.

| Agile Kanban | Lean kanban |

| Derived From Lean | Part of Lean |

| Defines Just In Time Delivery | Complements or part of Just In Time Manufacturing |

| Named after Lean kanban, consists of JIT delivery, kanban boards, process flow controls | Consists of kanban (visual signaling), or a kanban system using signal cards |

| Method for managing knowledge work | System for visualizing the status of work |

| Has a capital “K” | Has a lowercase “k” |

| Uses Work In Progress (WIP) to provide structure | May have cards that say WIP on them |

The Kanban Methodology in Agile

First, let us start with what it is not:

- It is not project management, nor does it have to be used exclusively within projects

- It is not a method specific to developing software

- It is not just post-its on a board you shove through from beginning to end – that is a kanban board.

Agile Kanban is about continuously delivering work output and ensuring that all aspects are as visual as possible.

Where other Agile approaches deliver incrementally, often with set iterations, Kanban is more of a continuous workflow. Work items need to be pulled through the processes. If there is no capacity, items are not pulled forward in the process flow and new items are not added to the queue.

Kanban Roles

Kanban defines no roles. Kanban describes a way to organize work to provide a continuous delivery stream of that work. The roles needed to perform that work are up to the organizations. You would not change out the existing way you do work, but implement Kanban within that existing structure.

In this way, Kanban is exceptionally versatile. It brings in the Agile values without a huge overhead of changes that make Agile frameworks sometimes prohibitive. If you like the way you work, but want to try and improve it, Kanban may be a solution.

The Work in Progress (WIP) Limit

Kanban works by limiting the Work in Progress (WIP). This allows some control over the flow of work. Advantages of this include:

- Reduced task switching

- Greater visible work status

- Improve any handoff of items

- Reduce work overlap

- Eliminate excessive meetings about the work

- Streamline the overall process

- Provide metrics and a structure of tracking the work getting done – which can provide the means to improve the overall flow of the work being performed

- Reduce inventory and obsolescence

Kanban Meetings

Kanban has 3 meetings

- The Daily Stand-up

- The Prioritization meeting

- The Retrospective

You can learn more about those here: What types of meetings should you have in Kanban?.

Little’s Law – Validating Kanban WIP Limits

Little’s Law helped to prove the idea behind JIT Manufacturing and JIT Delivery, through the study of people standing in lines. Little’s Law shows that a relationship exists between the average number of people in a line, their rate of arrival to the line, and the average time spent in the line.

If you think about a line (or queue), say a line in a grocery store waiting to check out, one person at a time is getting their groceries totaled up and paying. Once they are done, they exit the line and each person moves up one spot. If the flow of customers to the store increases, the line gets longer, the average duration of time spent in the line increases and the cashier’s work in progress increases. Hopefully, the store will open more registers, but probably not.

This seems fairly logical, you put more people in line and it takes them longer to get through the line. The customers can then become restless, perhaps they leave after an hour in the line and go somewhere else.

The psychological implications on the cashier of the long line, the one doing the work, may additionally cause him or her to slow down. They see this huge amount of work and come to the conclusion that they will never make any progress, maybe they go home frustrated and dream of quitting their job.

What can be done about this? Try to limit the number of people in the line. Open up extra cash registers when lines reach a certain length helping to keep the flow smooth.

The basic formula for Little’s Law in relation to Kanban is WIP = Throughput * Cycle Time.

L = λ W

WIP, or Work In Progress, is the average number of items in the process. Throughput is the average rate that the WIP items get through the workflow. With cycle time being the average time spent going from in progress to completion. If you want to increase throughput and cycle time, you can limit the Work in Progress.

Additional Books and Educational Material on Kanban

- IBQMI® Approved Kanban Professional: The official training material

- IBQMI Certified Scrumban Practitioner®: The official training material

- IBQMI Certified Kanban Coach: The official training material

- Kanban: Visualize work and maximize efficiency- Your guide to the basics

- Real-World Kanban: Do Less, Accomplish More with Lean Thinking

- Kanban: 3 Books in 1: Your Guide to the Basics+Beyond the Basics+Workflow Visualized: An Expert’s Guide

- PATboard Scrum Board and Kanban Board Full Toolset Magnetic

Reflection

To sum things up:

Agile Kanban = Just in Time Manufacturing – Manufacturing + Delivery

Agile Kanban ≠ kanban board

A better name for Agile Kanban would be Just in Time Delivery.

The basic idea was thought up by Taiichi Ohno while watching people grocery shop, and the efficiency of this system was proven through the use of Little’s Law. Of probably all Agile approaches, it is the most versatile. You take your existing business structure and shove Kanban into it. You can use it in Waterfall, and you can make it part of your daily work organization structure outside of projects. The key to that extra versatility lies in not defining the organizational structure and the focus on continuous delivery versus other Agile approaches incremental delivery.

Companies have also reported huge gains to productivity by implementing Kanban. It isn’t magical, but Kanban provides you with the ability to keep work under control as long as someone puts in the effort needed to control it.

Kanban on SlideShare:

Sources

IBQMI (2017), “Certified Kanban Coach; The Official Training Material” International Business and Quality Management Institute. Cheyenne, WY.

Toyota: Toyota Production System- http://www.toyota-global.com/company/vision_philosophy/toyota_production_system/

Informs – Information on John Little: https://www.informs.org/Explore/History-of-O.R.-Excellence/INFORMS-Award-Namesakes/Little-John-D.-C

Images from https://www.pexels.com/

Categories: Agile, Kanban, Lean Six Sigma

6 replies »